Why investing in jig and fixture tooling saves time and money long-term

Wiki Article

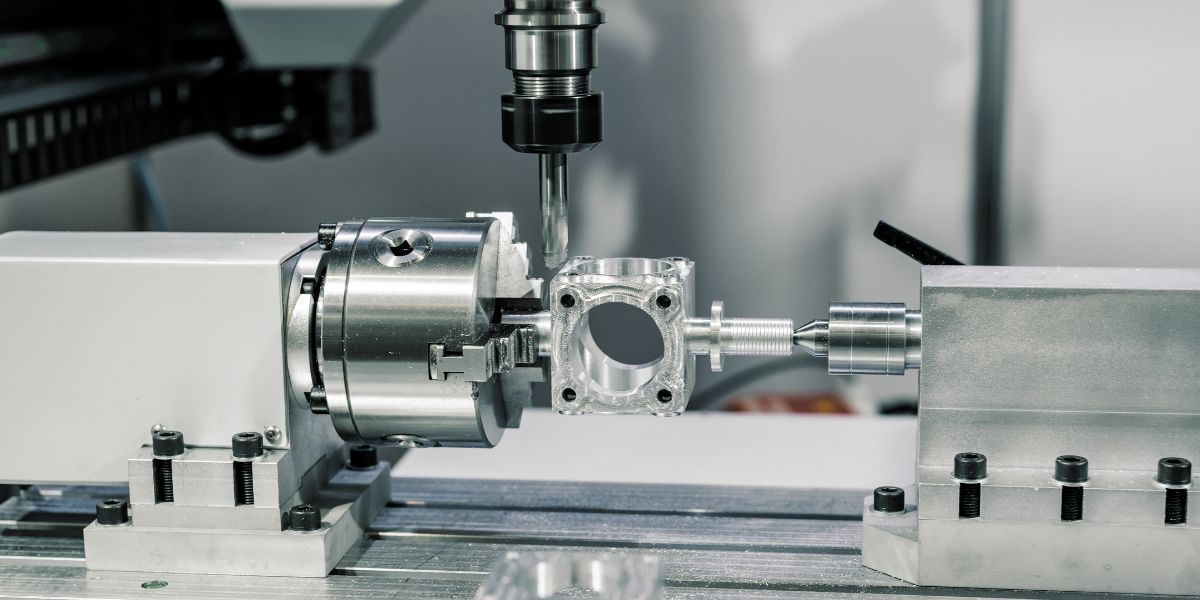

Discover the Perks of Using CNC Machining Solutions for Accuracy Engineering and Production

CNC machining solutions provide substantial advantages for precision design and manufacturing. By using innovative computer-controlled machinery, these services guarantee high degrees of accuracy and performance. This modern technology permits for the production of intricate elements from various materials, decreasing human mistake and production time. Nonetheless, the advantages expand beyond accuracy alone, meaning much deeper influences on productivity and cost-efficiency that are necessary for contemporary markets. Checking out these aspects discloses a much more comprehensive understanding of CNC machining's role.Enhanced Precision and Accuracy

As industries significantly require higher criteria, CNC machining solutions have actually become a necessary remedy for attaining boosted precision and accuracy in design applications. These services use sophisticated computer-controlled machinery to produce elaborate parts that fulfill rigid specs. The capability to program exact measurements lessens human mistake, guaranteeing that each component is made to exacting resistances.CNC machining is specifically valuable in industries such as aerospace, automobile, and medical tools, where accuracy is critical. The technology permits for the development of intricate geometries that standard machining methods might battle to accomplish. By utilizing CAD models, CNC equipments can duplicate designs with remarkable integrity, resulting in regular high quality across manufacturing runs.

Raised Efficiency and Productivity

Additionally, CNC innovation enables the synchronised processing of several parts, leading to higher production prices. The capacity to run equipments continually, even throughout non-working hours, makes best use of functional time and resource utilization. Furthermore, the fast setup and transition times linked with CNC machining facilitate quick adaptation to different task needs, making it possible for suppliers to react quickly to market demands.

Economical Production Solutions

Additionally, CNC machining enables for fast prototyping and manufacturing runs, which aids to streamline the production process and reduce preparations. The ability to produce intricate geometries with very little material waste even more adds to cost financial savings. cnc milling services near me. As an outcome, companies can allot funds extra successfully and purchase other locations of their operations. In general, CNC machining services provide a trustworthy pathway for organizations to boost earnings while preserving high requirements in product top quality and efficiency

Adaptability in Product Compatibility

The flexibility of CNC machining solutions in material compatibility is among its most considerable advantages. This capacity permits suppliers to collaborate with a varied series of materials, consisting of compounds, metals, and plastics. Each product can be carefully machined to fulfill details design demands, leading to elements that are both high-quality and useful. For light weight aluminum, circumstances and steel are frequently utilized for their strength and resilience, while plastics can be chosen for their corrosion-resistant and lightweight properties. CNC makers are geared up to take care of different product buildings, guaranteeing that the desired specifications are met with accuracy. This flexibility not just enhances the design possibilities however also makes it possible for makers to tailor their products to different market demands, from aerospace to clinical and automobile applications. Inevitably, the ability to efficiently use numerous materials streamlines the production procedure and widens the range of cutting-edge engineering options.Structured Prototyping and Layout Version

Improving the prototyping and layout version process is a vital benefit of advanced machining technologies. CNC machining services enable developers and engineers to promptly create exact models, helping with fast testing and examination. This effectiveness substantially decreases the moment from principle to production, allowing companies to repeat styles quickly based on real-world responses.Additionally, CNC machining's high accuracy minimizes errors, guaranteeing that each model carefully mirrors the final item specs. The ability to work with numerous products further improves the design opportunities, permitting for detailed testing across different circumstances.

Therefore, companies can improve their items extra effectively, adapting to market needs and consumer choices. This responsiveness is vital in today's affordable landscape, where technology cnc milling services near me and speed are extremely important. Making use of CNC machining solutions not just accelerates the growth procedure yet additionally enhances the overall top quality and integrity of the final produced items.

Often Asked Concerns

What Industries Benefit Many From CNC Machining Providers?

The aerospace, automobile, medical, and electronic devices industries profit most from CNC machining solutions. These sectors require high accuracy, intricate designs, and constant high quality, making CNC machining necessary for creating intricate components and meeting strict market requirements.How Does CNC Machining Contrast to Typical Manufacturing Approaches?

CNC machining uses greater effectiveness, accuracy, and flexibility compared to traditional production approaches. It minimizes human mistake, allows complicated designs, and permits fast prototyping, eventually causing better manufacturing top quality and decreased lead times.What Kinds of CNC Machines Are Typically Used?

What Is the Common Preparation for CNC Machining Projects?

The normal lead time for CNC machining projects normally varies from a couple of days to several weeks, depending upon variables like intricacy, material schedule, task size, and the maker's work, influencing total shipment timelines.Are There Any Limitations to CNC Machining Providers?

CNC machining solutions do have limitations, including product restrictions, complexity of styles, and dimension restrictions. Additionally, intricate geometries might need specialized tooling, which can enhance manufacturing time and prices, affecting general job usefulness.CNC machining solutions supply considerable advantages for accuracy engineering and manufacturing - cnc turning service. As industries progressively demand higher standards, CNC machining services have actually arised as a necessary option for accomplishing improved precision and accuracy in design applications. CNC machining solutions not only enhance accuracy however additionally considerably boost efficiency and performance in manufacturing procedures. CNC machining offers higher effectiveness, precision, and versatility contrasted to traditional production approaches. Typically made use of CNC equipments consist of CNC lathes, CNC milling makers, CNC routers, CNC plasma cutters, and CNC laser cutters

Report this wiki page